Occupational Safety & Health (OSH)

OSH Services offered by our firm are Ultrasonic Thickness Testing, Chemical Health Risk Assessment, Noise Risk Assessment, LEV Assessment, Indoor Air Quality Assessment and Chemical Exposure Monitoring. For more details please click on the links given below.

-

Chemical Health Risk Assessment (CHRA)

We offer Chemical Health Risk Assessment services to many industries at market leading prices.

Chemical Health Risk Assessment (CHRA)

We offer Chemical Health Risk Assessment services to many industries at market leading prices. -

Local Exhaust Ventilation (LEV)

Our team has registered hygiene technicians in DOSH in conducting the Inspection, Testing and Examination of LEV and GEV.

Local Exhaust Ventilation (LEV)

Our team has registered hygiene technicians in DOSH in conducting the Inspection, Testing and Examination of LEV and GEV. -

Chemical Exposure Monitoring

We offer extremely effective and efficient Chemical Exposure Monitoring services to our patrons in Malaysia

Chemical Exposure Monitoring

We offer extremely effective and efficient Chemical Exposure Monitoring services to our patrons in Malaysia -

Noise Risk Assessment

Assessment must carried out by DOSH Registered Noise Competent Person.

Noise Risk Assessment

Assessment must carried out by DOSH Registered Noise Competent Person. -

Ultrasonic Thickness Testing

As a leading service provider, we offer our customers with Ultrasonic Thickness Testing Service in Malaysia.

Ultrasonic Thickness Testing

As a leading service provider, we offer our customers with Ultrasonic Thickness Testing Service in Malaysia. -

Indoor Air Quality (IAQ) Assessment

We are engaged in offering the services of Indoor Air Quality Assessment in Malaysia.

Indoor Air Quality (IAQ) Assessment

We are engaged in offering the services of Indoor Air Quality Assessment in Malaysia. -

Medical Surveillance

Medical surveillance carried out under the USECHH Regulations must be conducted by an Occupational Health Doctor

Medical Surveillance

Medical surveillance carried out under the USECHH Regulations must be conducted by an Occupational Health Doctor -

Audiometric Hearing Test

It has been a legislation of noise exposure management and control for industries in Malaysia mainly targeting factory workplace environment

Audiometric Hearing Test

It has been a legislation of noise exposure management and control for industries in Malaysia mainly targeting factory workplace environment -

Biological Monitoring

Biological monitoring is a way of assessing chemical exposures by measuring the chemical or its breakdown products in a biological sample

Biological Monitoring

Biological monitoring is a way of assessing chemical exposures by measuring the chemical or its breakdown products in a biological sample -

Lighting Assessment (LUX)

To determine the current lighting level meets the requirements of Second Schedule Regulation 29

Lighting Assessment (LUX)

To determine the current lighting level meets the requirements of Second Schedule Regulation 29 -

Heat Stress Assessment

Recognize, estimate, prevent and treat heat stress at work

Heat Stress Assessment

Recognize, estimate, prevent and treat heat stress at work -

DOSO

Assessment is for non-major hazard installation as stipulated in Occupational Safety and Health

DOSO

Assessment is for non-major hazard installation as stipulated in Occupational Safety and Health -

CIMAH

The CIMAH Regulations are applicable to manufacturers undertaking industrial activities

CIMAH

The CIMAH Regulations are applicable to manufacturers undertaking industrial activities -

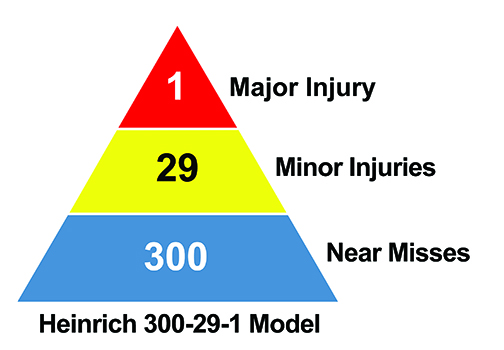

HIRARC

To provide a systematic and objective approach to assessing hazards and their associated risks

HIRARC

To provide a systematic and objective approach to assessing hazards and their associated risks -

SiRAC

A simple assessment involves a process of grouping workplace risks into control bands

SiRAC

A simple assessment involves a process of grouping workplace risks into control bands -

Safe Working in Confined Spaces

They have to ensure that the workers were certified whether they followed the guidelines

Safe Working in Confined Spaces

They have to ensure that the workers were certified whether they followed the guidelines -

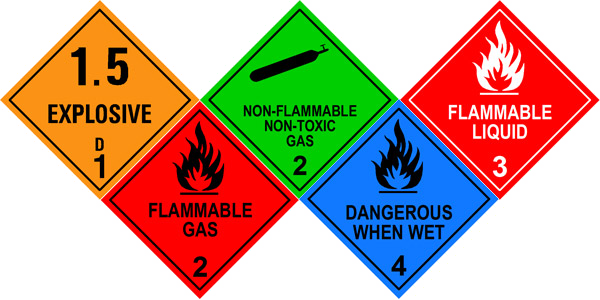

Combustible Gases Inspection

Our gas free inspections allow your staff to operate in a safe environment

Combustible Gases Inspection

Our gas free inspections allow your staff to operate in a safe environment -

Asbestos Testing

Modern research has revealed the link between asbestos and certain types of cancer

Asbestos Testing

Modern research has revealed the link between asbestos and certain types of cancer